Every October 31st, children and adults across the United States celebrate Halloween by collecting mountains of chocolate, gummies, and sugary treats. But what guarantees the safety and consistent flavor of these mass-produced confections?

Whenever Halloween nears, grocery stores fill up with large bags of assorted candies. But how do producers of these confections ensure that all that candy is safe to eat? How do they guarantee that every piece is made with the same ingredients and that each sweet bite is just as delicious as the last?

Addressing Quality Challenges: Batch Variation and Product Format Differences

For confectioners, maintaining absolute consistency across mass-produced candy is a major challenge. When candy is made in large batches, slight variations in processing, ingredient sourcing, or storage can lead to chemical differences.

The Need for Analytical Quality Control

Exploring potential chemical differences between the same type of candy helps answer critical questions like: “Do these pieces taste different from each other?” and “Why do these pieces taste different?” Some possible reasons include:

- Mass Production Variability: Not all batches may be made exactly the same.

- Multiple Facilities: Differing storage conditions across production facilities (storage time, temperature, humidity) can impact quality.

- Product Formats: Variations exist across regular sized bars, mini-sized ones, and holiday-themed designs.

Analysis of these similar products helps consumer goods companies monitor quality control and batch variation, optimize process development, and understand shelf-life and aging.

Unwrapping the Flavor: Aroma Profiling with GC-TOFMS Technology

To ensure every piece of candy delivers the consistent flavor and aroma consumers expect, labs turn to high-precision analytical methods. LECO’s state-of-the-art laboratory equipment, like the Pegasus BT Series and ChromaTOF Sync data alignment software, is designed to help labs rapidly unwrap the aroma profile and chemical composition of their candy.

Proof-of-Concept Study: Analyzing Candy Aroma Profiles

In our lab at LECO HQ, we took a look at three different product format variations of the same brand of candy. Using the Pegasus BT Series instruments and ChromaTOF Sync data alignment software, we were able to apply a reliable workflow that allowed trends and differences of the products’ aroma profiles to be quickly extracted from the data set and evaluated. The ability to harness the power of high-quality TOF mass spectral data allows for automatic deconvolution and identification of these key patterns.

Key Findings: Identifying Chemical Differences in Flavor Compounds

In this proof-of-concept study, some notable differences were observed between the samples. Uncovering these similarities and differences in the aroma profile allowed for new questions to be asked, specifically around consumer perception.

PCA plot results

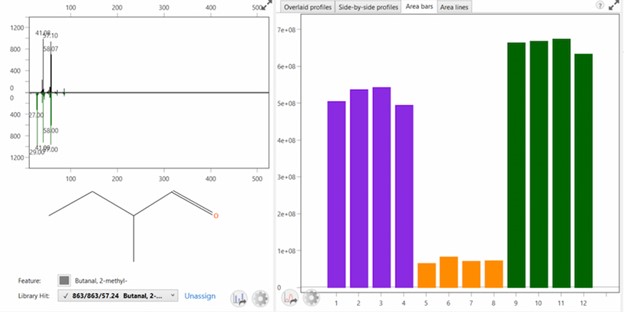

2-Methyl-Butanal: Some analytes, like 2-Methyl-butanal, clearly varied between the samples. The aroma of this compound is “chocolate/caramel/cereal/biscuit/fatty”.

Methyl-Pyrazine: Significant aroma variations can also be seen for Methyl-Pyrazine, which provides a “coffee/cocoa/nutty/roasting” character to products.

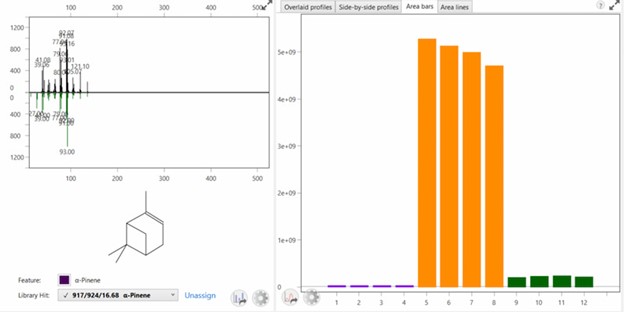

Alpha-Pinene: An additional point of interest was significant variation in alpha-pinene, which stands out in one of the variants. Alpha pinene is a key component of many essential oils and natural ingredients. Its presence could indicate it is deliberately part of a candy formulation, or it could signal cross-contamination from a previous production batch.

By identifying these trace components, LECO’s advanced instrumentation puts you a step ahead in answering your questions on quality, product development, and competitor product formulations.

Explore LECO Analytical Solutions

The power of high-quality TOF mass spectral data provided by our instruments allows automatic deconvolution and identification of key trends and patterns in your data sets.

Next Steps in Food Quality & Safety

Ready to ensure the absolute safety and quality of your food products? Explore the capabilities of our Pegasus BTX and see how ChromaTOF software can make your lab more efficient today.

You can also read all about our solutions for Food Safety and register for upcoming webinars, download application notes, and learn more about comprehensive food analysis techniques.

Frequently Asked Questions (FAQ)

What is Aroma Profiling in Candy?

Aroma profiling involves analyzing the volatile organic compounds (VOCs) that make up a product’s unique smell and taste. By analyzing these compounds using instruments like the Pegasus BT Series, manufacturers can ensure flavor consistency and detect off-flavors or contaminants.

How Does GC-TOFMS Relate to Food Safety?

GC-TOFMS (Gas Chromatography – Time-of-Flight Mass Spectrometry) is a powerful tool in food safety and quality control. It can identify and quantify hundreds of compounds, including trace-level contaminants (like pesticide residues or packaging migrants) and natural flavor compounds, ensuring product safety and quality consistency across batches.

Can LECO Equipment Detect Contaminants in Candy?

Yes. While this article focuses on flavor components, LECO’s GC-TOFMS instruments are often used for broader food safety applications, including the detection of harmful or regulated substances like pesticide residues, environmental contaminants, and adulterants at ultra-trace levels.